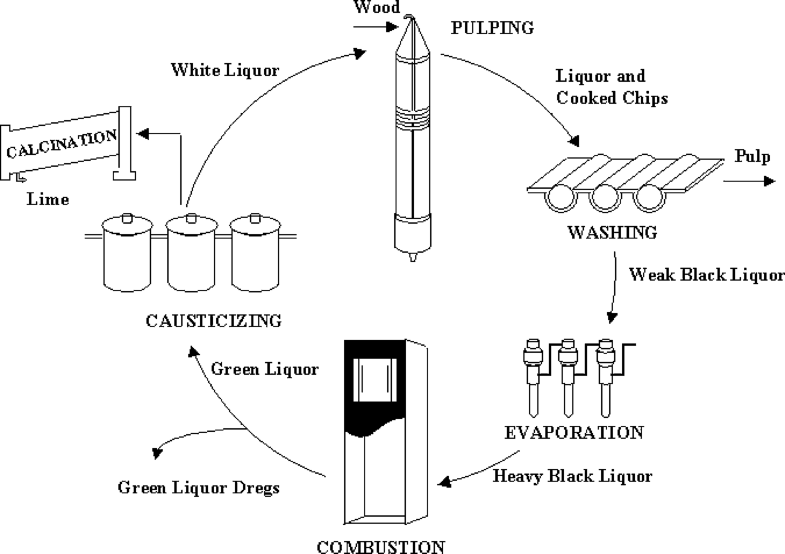

Green Liquor Kraft Process . Quick lime is slaked in the smelt solution. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. the kraft chemical recovery process is a mature, effective technology that provides for recycling of. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. Green liquor from the dissolving tank and, the. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. a closed cycle process with 3 main functions: the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom.

from link.springer.com

cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. a closed cycle process with 3 main functions: Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. Green liquor from the dissolving tank and, the. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. Quick lime is slaked in the smelt solution. the kraft chemical recovery process is a mature, effective technology that provides for recycling of.

Green liquor dregs as an alternative neutralizing agent at a pulp mill SpringerLink

Green Liquor Kraft Process a closed cycle process with 3 main functions: — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. a closed cycle process with 3 main functions: Green liquor from the dissolving tank and, the. Quick lime is slaked in the smelt solution. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. the kraft chemical recovery process is a mature, effective technology that provides for recycling of. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom.

From ar.inspiredpencil.com

Kraft Process Diagram Green Liquor Kraft Process cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. a closed cycle process with 3 main functions: the spent inorganic chemicals form a smelt composed of sodium carbonate. Green Liquor Kraft Process.

From docslib.org

Hemicellulose Extraction from South African Eucalyptus Grandis Using Green Liquor and Its Impact Green Liquor Kraft Process the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. — kraft. Green Liquor Kraft Process.

From www.researchgate.net

(PDF) • “The "Carbonate Effect" An important concept to explain the efficiency of green liquor Green Liquor Kraft Process Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. cooking liquor (white liquor) for the kraft. Green Liquor Kraft Process.

From ar.inspiredpencil.com

Kraft Process Diagram Green Liquor Kraft Process a closed cycle process with 3 main functions: Green liquor from the dissolving tank and, the. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. — kraft papermaking involves a complex cycle of transforming. Green Liquor Kraft Process.

From ar.inspiredpencil.com

Kraft Process Diagram Green Liquor Kraft Process a closed cycle process with 3 main functions: — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. Quick lime is slaked in the smelt solution. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. green liquor is the dissolved. Green Liquor Kraft Process.

From ar.inspiredpencil.com

Kraft Process Diagram Green Liquor Kraft Process — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. Quick lime is slaked in the smelt solution. the kraft chemical recovery process is a mature, effective technology that provides for recycling of. a closed cycle process with 3 main functions: the spent inorganic chemicals form a smelt composed of sodium. Green Liquor Kraft Process.

From www.scribd.com

Kraft Black Liquor, Green Liquor, Brown Stock Application PDF Pulp (Paper) Chemistry Green Liquor Kraft Process — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. Green liquor from the dissolving tank and, the. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide,. Green Liquor Kraft Process.

From www.researchgate.net

(PDF) A review of green liquor scale formation Green Liquor Kraft Process Quick lime is slaked in the smelt solution. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. a closed cycle process with 3 main functions: the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. Eliminate. Green Liquor Kraft Process.

From ar.inspiredpencil.com

Kraft Process Diagram Green Liquor Kraft Process Green liquor from the dissolving tank and, the. a closed cycle process with 3 main functions: Quick lime is slaked in the smelt solution. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. green liquor is. Green Liquor Kraft Process.

From link.springer.com

Green liquor dregs as an alternative neutralizing agent at a pulp mill SpringerLink Green Liquor Kraft Process the kraft chemical recovery process is a mature, effective technology that provides for recycling of. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. Green liquor from the dissolving tank and, the. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and.. Green Liquor Kraft Process.

From www.slideserve.com

PPT Pulping and Bleaching PSE 476 PowerPoint Presentation ID149682 Green Liquor Kraft Process Green liquor from the dissolving tank and, the. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper.. Green Liquor Kraft Process.

From blog.electronmachine.com

Green Liquor Process Management with Inline Refractometers InLine Process Refractometers for Green Liquor Kraft Process cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom.. Green Liquor Kraft Process.

From www.pro-sonix.com

ap16 green liquor ProSonix Green Liquor Kraft Process cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. Quick lime is slaked in. Green Liquor Kraft Process.

From gaspaperdryer.org

Source Aqeel Zaidi, PE, UnionGas Co, CIGC IGT Presentation, 7/2000 Green Liquor Kraft Process Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. the kraft chemical recovery process is a mature, effective technology that provides for recycling of. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. cooking liquor (white liquor) for the kraft. Green Liquor Kraft Process.

From www.researchgate.net

(PDF) Influence of green liquor and AQmodified kraft pulping on fiber hexenuronic acid and Green Liquor Kraft Process Quick lime is slaked in the smelt solution. the kraft chemical recovery process is a mature, effective technology that provides for recycling of. Green liquor from the dissolving tank and, the. a closed cycle process with 3 main functions: the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at. Green Liquor Kraft Process.

From www.researchgate.net

Flowsheet of the Kraft process under study. The materials sampled are... Download Scientific Green Liquor Kraft Process green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the. Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. cooking liquor (white liquor) for the kraft process is produced from smelt generated in the recovery boiler. — kraft papermaking involves a. Green Liquor Kraft Process.

From www.slideshare.net

Kraft process Green Liquor Kraft Process Eliminate the waste material (black liquor) recover pulping chemicals (naoh and na2s) generate steam and. the spent inorganic chemicals form a smelt composed of sodium carbonate and sodium sulphide, which is collected at the bottom. Green liquor from the dissolving tank and, the. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from. Green Liquor Kraft Process.

From www.pulpandpapercanada.com

The role of sulfidity during kraft pulping Pulp and Paper CanadaPulp and Paper Canada Green Liquor Kraft Process the kraft chemical recovery process is a mature, effective technology that provides for recycling of. — kraft papermaking involves a complex cycle of transforming wood chips into pulp and paper. Green liquor from the dissolving tank and, the. Quick lime is slaked in the smelt solution. green liquor is the dissolved smelt of sodium carbonate, sodium sulfide. Green Liquor Kraft Process.